Services

Our Services

Engineering

Lorem ipsum dolor sit amet consectetur etry adipiscing elit maur dapibus vitae.

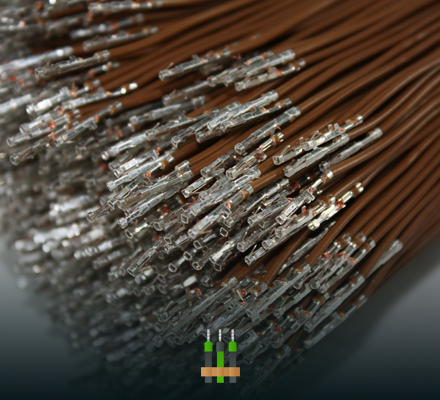

Wiring Harness

Lorem ipsum dolor sit amet consectetur etry adipiscing elit maur dapibus vitae.

Wiresets

Lorem ipsum dolor sit amet consectetur etry adipiscing elit maur dapibus vitae.

Wire harness production fully automated in precision and innovation

Core competence wire harness production

Our company specializes in the production of wire sets or strand sets for the wiring of control cabinets and control boxes.

We manufacture all batch sizes for our customers, from one piece.

For us, there is only one thing in the focus:

To guarantee you the highest quality standards and the best service.

We are enthusiastic about the matter, solid, technologically perfect and always on the way to the best and most efficient solution. We maintain relationships with integrity and open relationships with our customers and suppliers.

Our Zeta 640 wire processing center from Komax enables us to produce fully automated and innovative stranded sets for wiring control cabinets and control boxes.

The processing center offers maximum flexibility for specific production in a wide range of applications with a favorable price level.

Our Zeta is equipped with 5 process modules. This enables you as a customer to offer versatile and, above all, new possibilities for small batches with sequential bundling.

The cross-section range ranges by default from 0.22 to 6mm².

However, larger cross-sections (>6mm²) can be produced on alternative cutting systems. We can thus fully operate and cover the strand set cross-sectional range of 0.08-75mm².

Most stranded sets can be manufactured completely and without any conversion processes.

Features of our wire processing center

- Equipped with 4 crimp presses

- One combination station for five wire end sleeves

- Round-Bundler

- Sequential-Bundler

- Inkjet system in color red (ensuring readability next to strands manufacturer information)

- Automatic cable changer with up to 36 different lines

- Large cross-sectional area: 0.22 to 6mm²

- Reliable workmanship with high quality

- Fully automatic production guarantees consistently high quality

- Fully automated quality inspection modules

This configuration makes the system highly flexible and there are few limits to your orders.

The system is programmed fully automatically via our bundle master. It is the software that enables us to process your data from a manufacturing and commercial point of view and transfer it to our Komax Zeta. Simultaneously, data is transferred to our ERP system, which then controls the raw material stocks, calculates delivery times and orders goods that are not in stock.